ProfilCoat

Precision engineer tools. When accuracy and small tolerances are required – then the time of the VACUMAT ProfileCoat has come. Its diversity allows the coating of specified areas straight to the point. Online or offline – the entire surface solutions made by Schiele.

Individual system concepts enable profile and coating changes within a few minutes. Your profiles can be order-related coated and thereby present the opportunity to react towards individual client wishes in a fast and flexible manner.

Scope of application

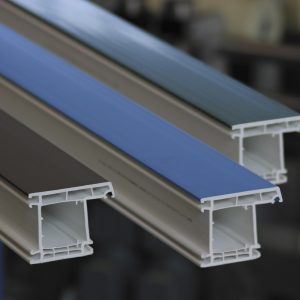

- PVC profiles

- Plastic profiles

- EPDM profiles and rubbers

- Metal profiles made out of aluminium, metal sheets etc.

- All lengthwise directed workpieces or strand cast products that need to be coated within a production process

Performance features

- Even coating of sections in one pass, especially for complex geometries.

- A procedure without waste and overspray that ensures reduced unit costs.

- A sophisticated matrix system that allows fast profile changes. If needed the entire production line can be converted within a few minutes at the touch of a button.

If necessary, the entire line can be converted within minutes at the push of a button. - The VACUMAT ProfileCoat® is equipped with a special internal coating. In combination with a dewpoint-controlled cooling system, the cleaning time is considerably reduced. Frequent colour changes can be executed fast.

- Self-sufficient coating management controls processing parameters and intervenes when needed to ensure optimal conditions.

- The entire surface concept is designed by Schiele and aims to meet your requirements.

- Applicable as a separate coating station both online and offline.

- With the help of special masking tools, specific sections are handled exclusively.

- Brilliant surfaces. Layer thicknesses from 10 to 200g/m², depending on the coating system.

- Diverse coating media are applicable, for instance, water-based coating material, UV 100% coating or water-UV coating.

- Process technology by Schiele’s founder of the VACUMAT technology – safe and reliable

- High production safety. The VACUMAT® is designed to run 24 hours during continuous operation.