AquaPaint

Play without limits. Do you have workpieces that do not fit into any of the IMPREGMAT designs? Oversizes? Special formats? Unusual applications? Then you have come to the right place. We can individually adapt the technology to your needs. Based on the knowledge of the inventor of brushing machine technology, the tailor-made solution grows during the course of the project.

Properties

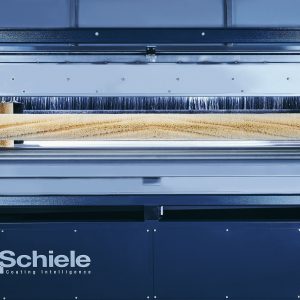

Made completely of stainless steel and optionally coated with Teflon, the Aquapaint is easy to clean. All drive elements are external and protected against corrosion. The brush drive is not installed in the floor area, but at the side and on top. Thus no medium penetrates into the drive mechanism during continuous operation.

Special flood nozzles ensure ideal saturation of all hard and soft wood areas. The driven brushes carefully work the coating medium and evenly smooth the surface. The filtered material is returned to the circuit. Easy on the wallet.

Suitable for

Water-based varnishes and glazes or solvent-containing systems with a viscosity of max. 25 sec. DIN4-jar.

Technical data

| Aquapaint | |

|---|---|

| Rate of Feed | according to layout |

| Electrical data | according to layout |

| Compressed air | according to layout |

| Electrical input (max) | according to layout |

| Length of basic machine | according to layout |

| Weight of basic machine | according to layout |

| Working height | according to layout |

| Guiding rail | according to layout |

| Flash point of the application media | above 55°C (no EX-protection!) |

| Workpiece width (max.) | according to layout |

| Workpiece height (max.) | according to layout |

| Workpiece length (min.) | according to layout |

| Brushes | according to layout |